What if your compliance team could see everything, everywhere, all at once?

For manufacturing leaders today, that’s not a futuristic fantasy. It’s becoming a necessary reality. As regulatory bodies tighten standards and workplace incidents carry heavier consequences, the old way of managing compliance is breaking down Learn how AI supports compliance in retail environments. Manual checklists, periodic inspections, and reactive investigations simply can’t keep pace with the complexity of modern manufacturing operations.

We’ve watched manufacturing teams struggle with an impossible task: maintaining perfect visibility across vast production floors while managing documentation, responding to incidents, and proving compliance during audits. The pressure is real, and the stakes have never been higher.

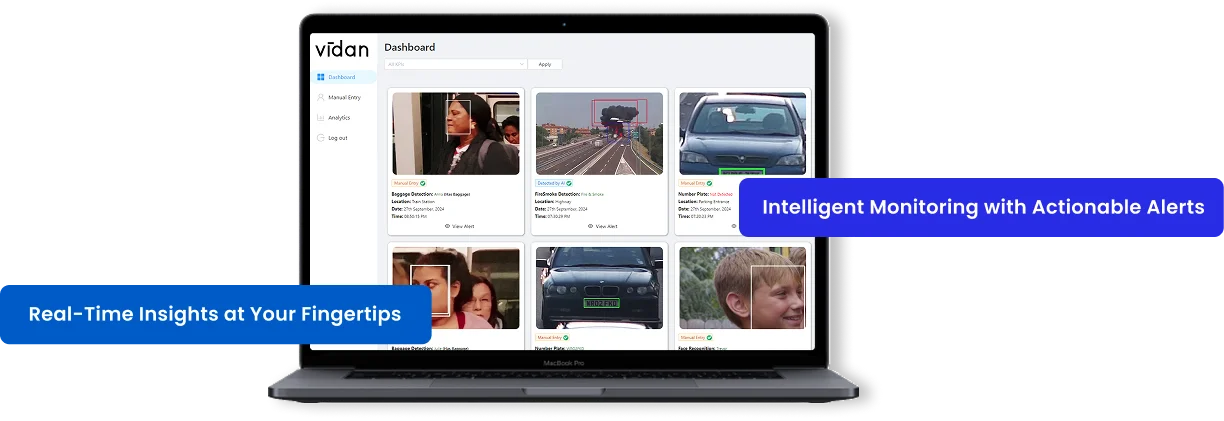

That’s exactly why AI in manufacturing compliance isn’t just another tech trend. It’s a fundamental shift in how plants maintain safety, meet regulations, and protect their people. At Vidan AI, we’re part of this transformation, and we want to show you how video intelligence is changing the compliance game for manufacturing facilities worldwide.

The Mounting Pressure: Why Traditional Compliance Is Failing Manufacturing

Walk into any manufacturing plant today and ask the compliance officer how they’re keeping up. You’ll likely hear the same story we hear from facility after facility.

Regulatory requirements have multiplied. OSHA standards, environmental protocols, quality certifications, and industry-specific regulations create a web of obligations that grows more complex each year. One automotive parts manufacturer we spoke with mentioned tracking over 200 separate compliance checkpoints across their production lines.

Meanwhile, the tools haven’t evolved. Most plants still rely heavily on:

Manual observation and reporting. Supervisors walking the floor with clipboards, trying to catch violations in real time. It’s exhausting and riddled with human limitations. No one can be everywhere at once, and even the most diligent observer will miss critical moments.

Reactive incident investigation. Something goes wrong, then teams scramble to piece together what happened from witness statements and fragmented records. By then, the opportunity to prevent the incident has long passed.

Periodic audits that create panic. Rather than continuous compliance, facilities operate in cycles of preparation and stress. Teams work overtime before audits, hoping they’ve covered all bases and dreading what inspectors might uncover.

The result? Manufacturing compliance has become a constant source of anxiety rather than a systematic advantage. Workplace safety monitoring gaps lead to preventable incidents. Documentation burdens pull supervisors away from their core responsibilities. And when audits do happen, proving compliance becomes a scramble through incomplete records.

We’ve seen compliance officers who can’t sleep the night before an audit. Plant managers who discover safety violations only after someone gets hurt. Operations teams are buried under paperwork instead of improving processes.

This isn’t sustainable, and manufacturing leaders know it.

How AI and Video Intelligence Fill the Gaps

AI in manufacturing bridges the blind spots that traditional monitoring can’t cover. With our video analytics for compliance, teams gain support in areas where manual observation falls short.

- It watches every zone at once without fatigue.

- It identifies patterns humans commonly miss

- It triggers alerts the moment conditions change. Similar alert systems are transforming smart cities.

- It reduces the burden of manual compliance reporting.

This shift gives safety, production, and compliance teams continuous workplace safety monitoring backed by real-time incident detection from the systems running on your existing cameras.

Real Scenarios Where AI Strengthens Compliance

PPE Enforcement During Heavy Shifts

When the floor gets busy, it’s easy to miss PPE lapses. Our system flags these moments instantly so supervisors can respond before a minor oversight becomes a risk.

Forklift and Pedestrian Near-Misses

High-traffic zones are a common source of avoidable incidents. Our detection models monitor these intersections around the clock and send alerts when unsafe distances occur. AI video analytics also support advanced traffic monitoring.

Audit Preparation

Instead of searching through hours of footage, teams pull organized, auto-tagged clips tied to events, timelines, and categories. This reduces errors and keeps documentation ready for auditors.

Spill or Hazardous Material Events

Spills and leaks need a rapid response. Real-time incident detection shortens reaction time so teams can take action the moment conditions shift.

How Vidan AI Powers This Transformation

Intelligent Detection That Understands Manufacturing

We’ve built our video analytics specifically for manufacturing environments. We understand the difference between authorized maintenance activity and unsafe behavior. We recognize manufacturing-specific PPE requirements. We adapt to your facility’s unique zones, equipment, and protocols.

When you implement Vidan AI, you’re deploying intelligence that learns your operation and gets smarter over time. Our system distinguishes between normal operational variance and genuine safety risks, reducing false alerts while maintaining vigilant monitoring.

Real-Time Analysis and Instant Alerts

Speed matters in safety. A violation that goes unaddressed for hours can become an incident. Our real-time incident detection processes video feeds continuously, analyzing behavior against your compliance rules and triggering immediate alerts when issues arise.

Alerts are intelligent and actionable. Vidan AI doesn’t just notify you thatnotify that something happened. It provides context: what was detected, where it occurred, who was involved, and what protocol was violated. Supervisors can review video evidence directly from the alert and take appropriate action instantly.

Comprehensive Reporting for Every Stakeholder

Different people need different insights from your compliance system. We provide reporting that serves everyone from floor supervisors to executive leadership.

Daily operational reports keep supervisors informed about compliance trends and recurring issues. Weekly analytics help plant managers identify systemic problems and allocate resources effectively. Monthly executive summaries give leadership visibility into facility-wide safety performance and compliance status. And when audits happen, comprehensive compliance documentation is available instantly.

Seamless Integration with Your Operations

We know manufacturing plants can’t afford disruptive technology implementations. That’s why Vidan AI integrates with your existing camera infrastructure and safety management systems. Implementation is measured in days, not months. Training is intuitive because the Vidan AI is designed for manufacturing professionals, not IT specialists.

Our goal is to enhance your operations, not complicate them. We become part of your team, providing the visibility and intelligence you need to maintain excellence in manufacturing compliance.

Daily Benefits for Teams Across the Plant

Production Supervisors

✓ Less manual monitoring

✓ Real-time alerts during busy operations

✓ Better control over high-risk areas

Safety Leaders

✓ Reliable, always-on workplace safety monitoring

✓ Event-based video evidence

✓ Stronger safety culture across shifts

Compliance Officers

✓ Organized, ready-to-use reporting

✓ Clear documentation for audits

✓ Reduced chance of missed violations

Plant Leadership

✓ Better visibility into risks

✓ Lower incident rates

✓ Higher confidence in compliance readiness

In Conclusion

Manufacturing compliance is undergoing its most significant transformation in decades. AI in manufacturing isn’t replacing human judgment; it’s amplifying it. Video intelligence isn’t about surveillance; it’s about partnership between technology and people in the service of safety.

We develop Vidan AI because manufacturing teams deserve better tools for the crucial work of keeping people safe and operations compliant. Every alert that prevents an injury, every audit that proceeds smoothly, every trend analysis that drives improvement represents technology serving its highest purpose: protecting people and enabling excellence.

Let’s have a conversation about how we can give you the visibility, confidence, and systematic excellence your manufacturing operation deserves. Because when it comes to safety and compliance, you shouldn’t have to choose between what’s possible and what’s necessary.

Your compliance challenges have a solution. We’re ready to show you how.